Description

New, Easier-to-Use Packaging

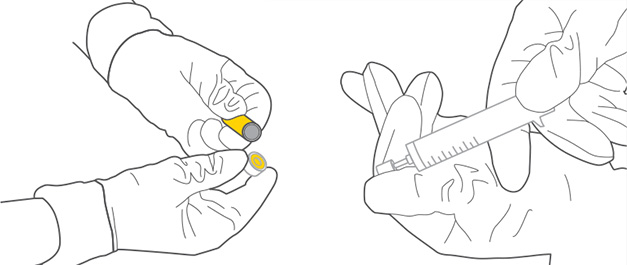

Screw-top tubes can be difficult to use, especially when wearing gloves.

We understand the importance of sampling efficiently while wearing the correct personal protective equipment, which is why our new Shell Water Detector tubes have flip caps.

These are easy to open and seal with one hand while wearing gloves. We also recommend using reverse-action syringes, which draw samples in when the plunger is pushed – an action that can be performed easily using one hand.

Trusted Worldwide

For over 50 years, operators across the world have relied on the Shell Water Detector to check their aviation fuel for suspended water that cannot be detected by visual inspections. The detector capsules are widely used, thanks to their effectiveness and simplicity.

Imitations are available, but, for quality you can trust, we recommend using the original, internationally recognised, industry standard that is the Shell Water Detector.

Check Your Fuel!

Low concentrations of water suspended in fuel cannot be detected by visual inspections. Thankfully, there is an easy-to-use test that you can rely on to verify that your jet fuel meets demanding aviation standards for water content.

The Shell Water Detector is a long-established and trusted industry-standard test for water in fuel. It is manufactured to Shell’s high quality requirements for reliable testing throughout the fuel supply chain.

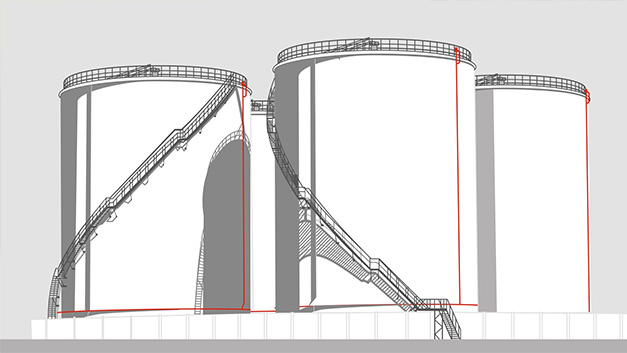

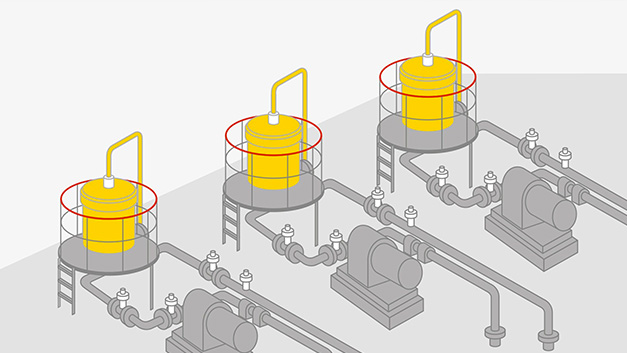

WHEN TO USE

Each in-service tank daily

Each filter drain (hydrant filter/loading filter) daily

Each fueller filter drain daily and as per JIG 1 5.3.1

Each hydrant dispenser daily and as per JIG 1 5.3.2

All fueller and trailer tanks daily and as per JIG 1 5.3.1

HOW TO USE

Check the Equipment

- Check the tube expiry date.

- Ensure that the sample jar is clean and free from water.

- Check that the 5-ml (0.2-fl-oz) syringe operates freely and that the nozzle is undamaged.

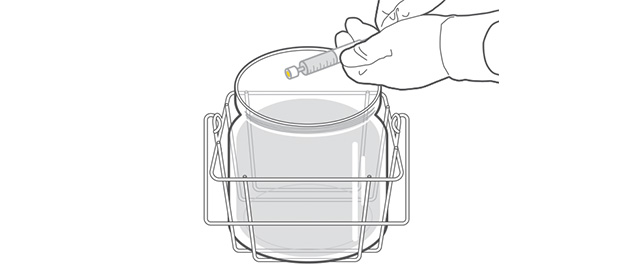

Fit the Capsule

- Remove a capsule from the tube. Do not touch or allow any moisture onto the yellow paper of the capsule.

- Close the tube to protect the remaining capsules from the ambient humidity.

- Check that paper is uniformly yellow. If it is not, use another capsule.

- Fit the capsule to the syringe with the plunger ready for use.

Draw a Sample

- Use the sample from the visual “clear and bright” check you have just completed.

- If you do not already have the sample, follow the visual inspection procedures (ASTM D4176).

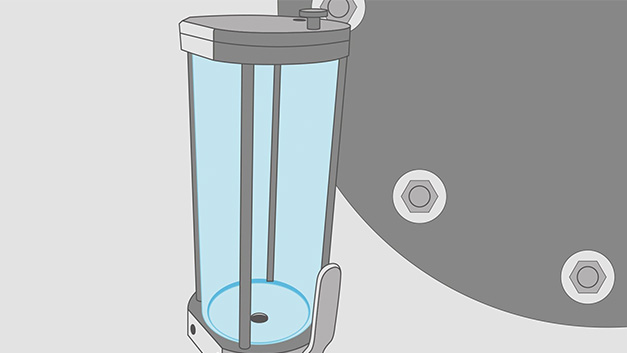

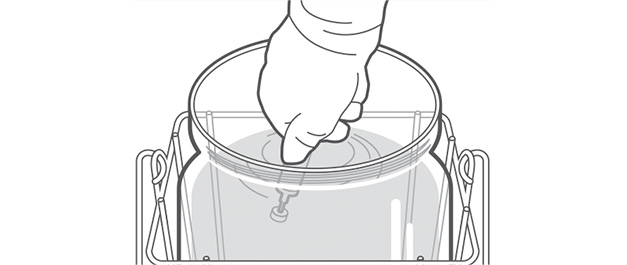

Immerse the Capsule In the Sample

- Ensure you are using gloves that are impervious to fuel.

- Immerse the capsule and about half the syringe in the sample and stir in a circular motion.

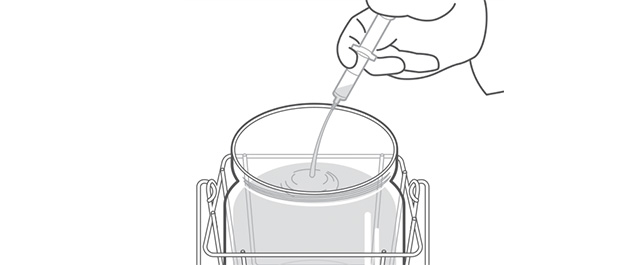

Extract the Sample

- Draw 5 ml of fuel into the syringe.

- Many operators favour a reverse action (single-handed) syringe, which draws a sample when the plunger is pushed, rather than a traditional syringe that needs holding in one hand while the other pulls the plunger.

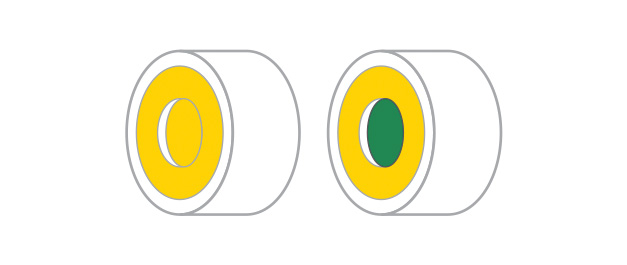

Withdraw the Syringe and Examine the Capsule

- Withdraw the syringe from the fuel and examine the capsule immediately for any colour change in the centre-wet area.

Results

The yellow wet area turns yellow–green in the presence of very low concentrations of dispersed water. The change to green becomes progressively more noticeable with increasing water content.

| Color | Result |

|---|---|

| No Change | Acceptable |

| A few green speckles or a slight change in color | Trace |

| Distinct color change | Suspended Water |

If there is any colour change, test a new sample to ensure that the first capsule was not faulty. If there is still a colour change with the second and a third test sample, water is present in the fuel.

After Sampling

- Dispose of the used capsule safely. It can only be used once. Empty the contents of the syringe back into the sample container and return to the recovery tank. Complete the documentation.